Thermal Spray

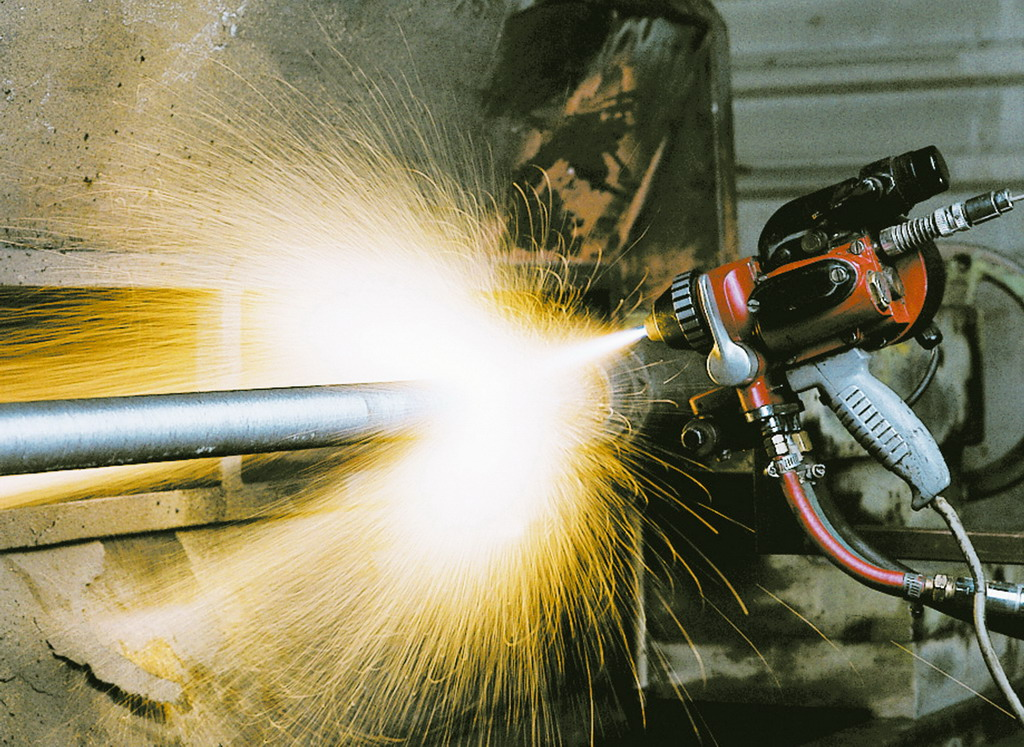

Thermal spraying is a surface engineering process that involves the application of a wide range of materials onto a prepared substrate. This process involves heating the chosen material to a molten or semi-molten state and then spraying it onto the substrate using a high-velocity jet of compressed air or gas. This creates a coating that bonds mechanically to the surface, providing protection against corrosion, wear, and erosion. Thermal spray coatings can also be used for decorative or functional purposes, such as providing electrical insulation or thermal barriers.

- Praxis’s thermal spray services include a variety of coating materials, including metals, ceramics, and polymers, as well as specialized coatings like tungsten carbide and diamond-like carbon.

- Praxis’s thermal spray services can be tailored to meet the specific needs of clients, whether it’s applying a new coating to protect against corrosion, restoring a damaged surface, or enhancing the performance of an existing component.

- Praxis’s thermal spray team includes highly skilled technicians and engineers with extensive experience in a variety of industries, including oil and gas, marine, aerospace, and more. They use state-of-the-art equipment and techniques to ensure the highest quality results.

- Praxis is committed to safety and environmental responsibility in all of its operations, and its thermal spray services are no exception. The company adheres to strict safety protocols and uses environmentally friendly materials and processes wherever possible.

Praxis provides thermal spray solutions for various industrial applications, including the oil and gas, aerospace, and marine industries. Our team of experienced professionals uses state-of-the-art equipment and technology to ensure the highest quality coatings are applied. We offer a range of thermal spray coatings, including flame spraying, arc spraying, plasma spraying, and high-velocity oxygen fuel (HVOF) spraying, each with its unique benefits and applications.

Our thermal spray solutions are tailored to meet the specific needs and requirements of each client, ensuring that the coatings are applied efficiently and effectively. We can also provide surface preparation services to ensure that the substrate is properly cleaned and prepared before the thermal spray process is applied. Our team of experts can advise on the best coating material and process to achieve the desired outcome, ensuring that the coating meets or exceeds the required performance criteria.

At Praxis, we are committed to providing the highest quality thermal spray coatings and services. Our team is dedicated to providing innovative solutions to help our clients protect their assets, extend the life of their equipment, and reduce maintenance costs. We also offer inspection and testing services to ensure that the coatings are performing as expected, providing our clients with peace of mind and confidence in the longevity and effectiveness of their thermal spray coatings.